10-12kg Houseused Food Freeze Dryer For Fruit

OVERVIEW

Lyophilization or freeze drying is a process in which water is removed from a product after it is frozen and placed under a vacuum, allowing the ice to change directly from solid to vapor without passing through a liquid phase. The process consists of three separate, unique, and interdependent processes; freezing, primary drying (sublimation), and secondary drying (desorption).

FEATURES

1. In-situ pre-freeze drying.

2. Temperature adjustable, controllable production process.

3. 30 sections can be set, the freeze dryer can modify the program parameters during the running process, and record the vacuum drying curve and data online.

4. Touch screen, you can set the power-on password to display the drying curve.

5. The square tray is not easy to be deformed, easy to operate and easy to clean.

6. The drying chamber adopts a high light transmissive colorless transparent plexiglass door, which can clearly observe the change process of the material during the operation.

7. Optional configuration of the inflation valve, which can be filled with dry inert gas.

SPECIFICATIONS

Model | LFD-10 |

Freeze-dried Area(M2) | 0.92M2 |

Handling Capacity (Kg/Batch) | 10~12Kg/Batch |

Cold Trap Temperature(℃) | <-35℃(No-load) |

Maximum Ice Capacity/Water Catch (Kg) | 6.0kg |

Layer Spacing(mm) | 38mm |

Tray Size(mm) | 430mm*265*25mm 8Pcs |

Ultimate Vacuum(Pa) | 15pa(No-load) |

Vacuum Pump Type | 2XZ-4 |

Pumping Speed(L/S) | 4L/S |

Noise(dB) | 64dB |

Power(W) | 2500W |

Power Supply | 220V/50HZ or Custom |

Weight (Kg) | 130Kg |

Dimension(mm) | 640*680*1180mm |

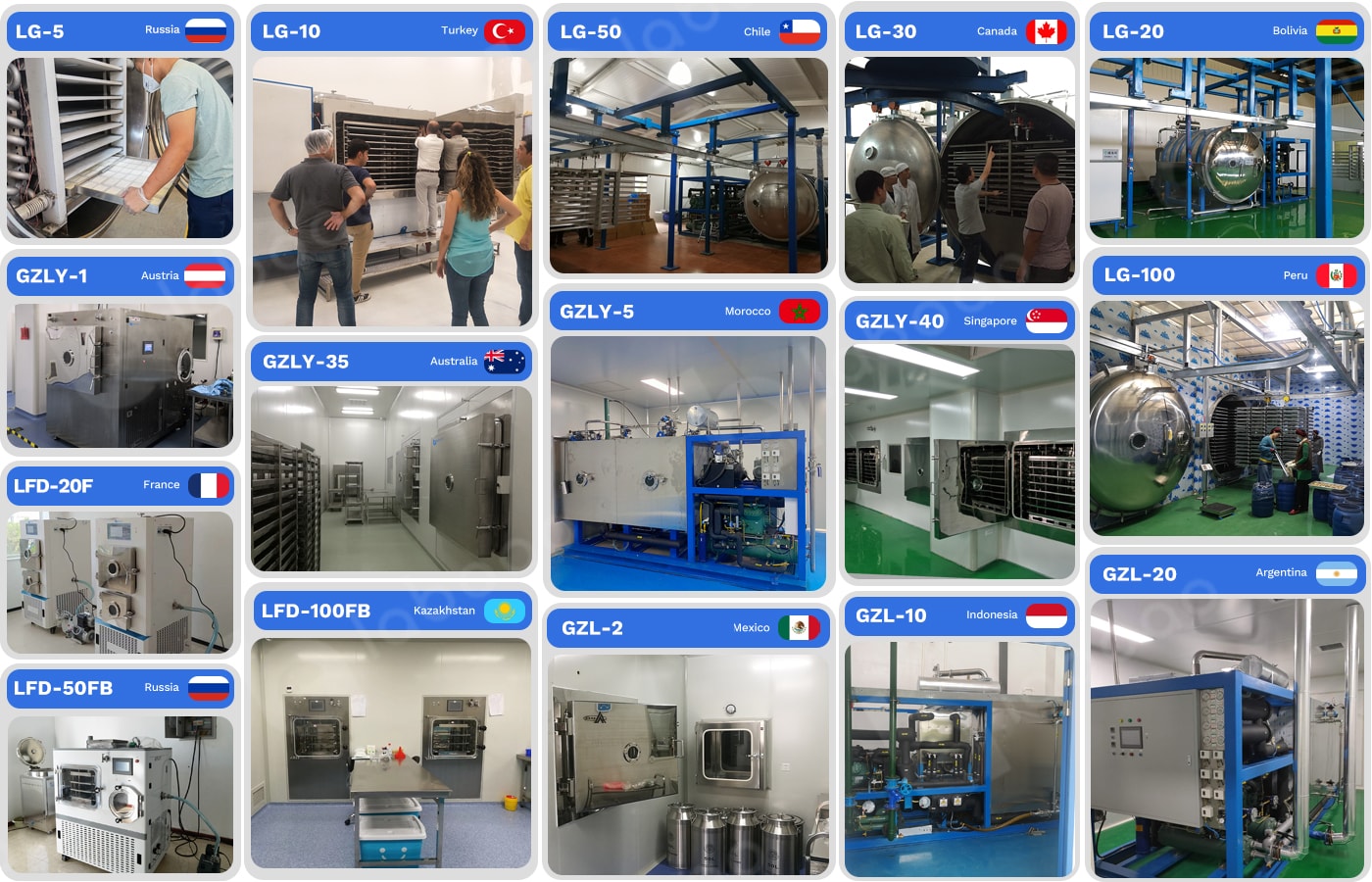

CUSTOMER CASE