The following detailed analysis of its technical advantages and potential risks from three core perspectives provides professional reference for users:

1. The Core Advantage of "Temperature Control on Each Shelf": A Key Guarantee for Uniform Freeze-Drying

The temperature control method for the shelf in a home freeze dryer is a key factor in determining the freeze-drying quality of food. Compared to traditional "single temperature control" (which relies on a single sensor at the top or bottom to control overall heating, resulting in significant temperature variations between shelves), independent temperature control on each shelf offers three irreplaceable advantages: ensuring consistent freeze-dried food quality across all shelves; improving freeze-drying efficiency and reducing energy consumption; and reducing food loss and improving rehydration properties, directly addressing the pain points of uneven heating and inconsistent freeze-dried food quality in home freeze-drying.

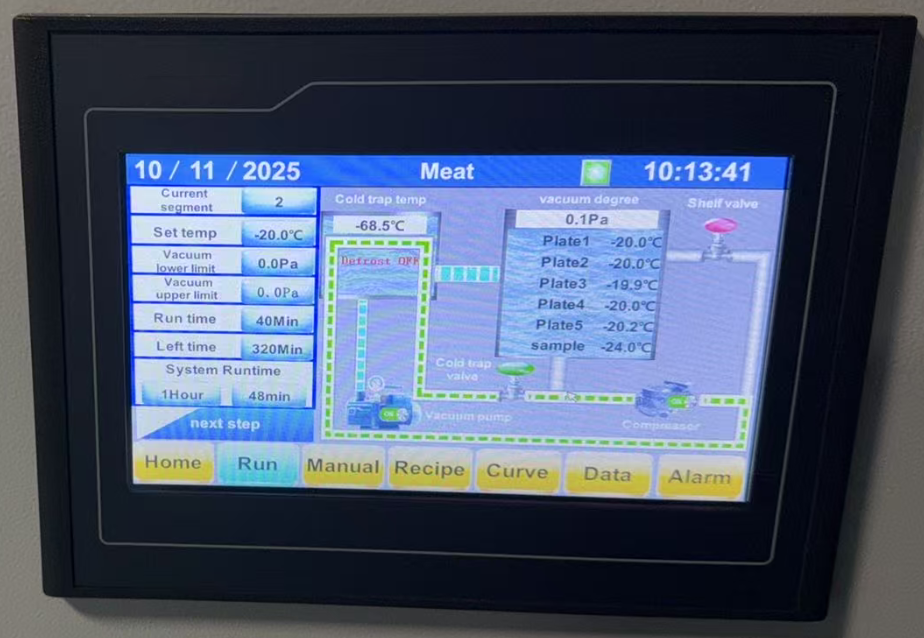

2. The "Required Display" of the Cold Trap Temperature: A Dual Guarantee of Safety and Efficiency

The cold trap is the core condensation component of a home freeze dryer. Its function is to condense the water vapor generated by the sublimation of food into ice crystals, maintaining the high vacuum environment within the freeze-drying chamber. The real-time display of the cold trap temperature is not an "additional function", but a "necessary condition" to ensure the safe operation of the equipment and the freeze-drying effect. It is mainly reflected in three aspects: real-time judgment of the freeze-drying process to avoid "ineffective operation"; early warning of equipment failure to protect the refrigeration system; ensuring the safety of food and avoiding the growth of microorganisms.

3. The Serious Consequences of Not Polishing Cold Trap Weld Joints: A Double Hazard to Equipment Lifespan and Food Safety

The weld joints of a cold trap are critical details in equipment manufacturing. Their surface treatment (especially polishing) directly impacts the equipment's sealing, corrosion resistance, and food safety. Failure to polish weld joints can lead to three irreversible consequences, seriously impacting the user experience and safety of home freeze dryers. Impurities in the welds can contaminate food; corrosion can accelerate, shortening the cold trap's lifespan; and seals can be compromised, affecting freeze-drying results.