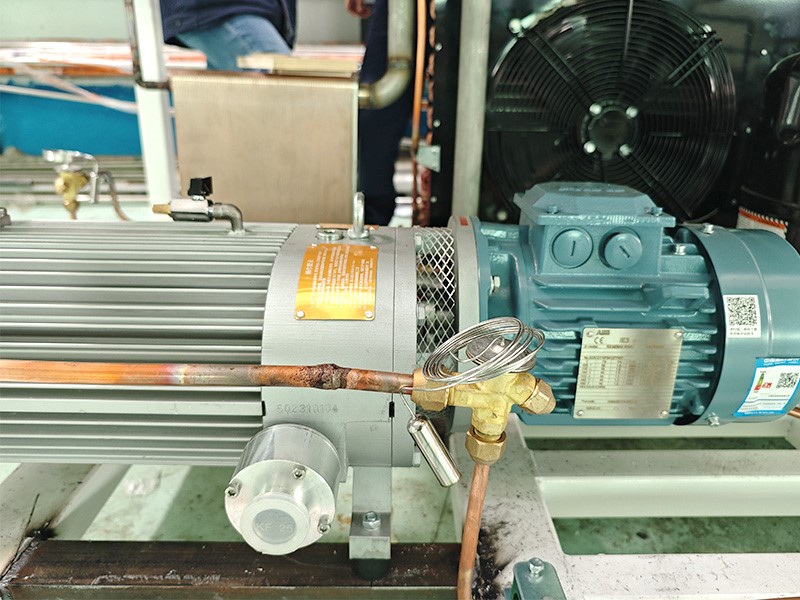

There are two major impacts on water inflow into the vacuum pump: airflow problems, refrigeration and vacuum problems, which mainly involve airflow direction, airflow channels, system refrigeration, related temperature, pressure, vacuum configuration and control process, etc. These aspects do not affect the water inflow of the vacuum pump independently, but should actually affect each other. To solve the problem of water inflow into the vacuum pump, these factors need to be considered comprehensively. Below we make a detailed analysis of the airflow problem.

Airflow issues affecting water ingress into the vacuum pump primarily manifest as uneven frost on the condenser (water trap) coil surface, varying thickness within a single coil, or even partial frost-free coils. While the refrigeration capacity meets full-load requirements and the coil temperature reaches a certain level (i.e., the coil temperature and vacuum are sufficient to capture water vapor at full load), the airflow distribution and direction of the airflow prevent it from passing through some coils, preventing the water vapor from entering the vacuum pump.

1. When water vapor sublimates from the freeze-drying chamber to the condenser, it first passes between the diaphragm valve and the intermediate channel. Therefore, the distance between the diaphragm valve and the coil, as well as the distance between the airflow baffle, coil, and diaphragm valve within the condenser, directly affect the airflow distribution and direction upon entering the condenser. Furthermore, the stroke of the hydraulically actuated diaphragm valve is also a factor to consider.

2. Coil layout. The distribution of multiple coil groups should be determined based on the direction of airflow after it passes through the diaphragm valve and airflow baffles, combined with the position of the vacuum tubes. In other words, the freeze-drying chamber serves as the source of water vapor generation, and the vacuum tube position in the condenser serves as the source of vacuum pressure. Simulation analysis is conducted based on these two starting and ending points. The airflow distribution from beginning to end is analyzed and analyzed. Reasonable coil calculation and layout are performed under the premise of ensuring uniform evaporation area and refrigerant distribution, that is, matching the system cooling capacity and cooling distribution, including a large ice capture capacity and a large sublimation rate for different products. The spatial layout of the coils, the number of coil groups, the length of each group and coil (taking into account the evaporation path of the Freon), and the surface area of the coils must all be comprehensively calculated and considered. Furthermore, adding additional airflow baffles can effectively achieve uniform airflow distribution. In addition, different coil arrangements also determine the shape and size of the condenser, as well as the layout and size of the entire freeze dryer. The layout of the coil is critical when considering the water inlet of the vacuum pump, and it is also a point that involves a wider range of aspects, so comprehensive consideration must be made during the planning and design stages.